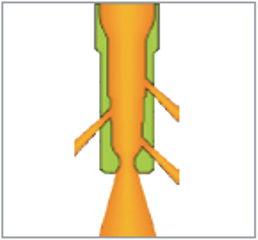

Multi-Port Center Jet

Break Through In Three Cone Rock Bit Hydraulics

Reduce Bit Balling like never before, with new patented multi-port technology. Tested and patented internal cavity eliminates jet plugging. Normal center jets rob horsepower from the bottom of the hole; because of precision orientation, hydraulic horsepower is returned to the bottom of the hole when bit is in non-balling state. Precision orientation also significantly reduces tooth erosion. Jet velocity is maintained at same rate from every orifice on bit.

MULTIPORT CENTER JET NOZZLE TEST

GALVESTON BAY, TEXAS

Providing the advantage of three additional jet streams in a roller cone bit design, the Multiport Center Jet nozzle can clean the entire cutting structure, significantly reducing bit balling. Because of their orientation between cones, the additional jet streams can un-ball the bit and then return to impacting the bottom of the hole, keeping penetration rates high and drilling longer.

In the sticky gumbo of the two Galveston Bay Wells, one 17 1/2 inch hole section was drilled to 4000 feet using a bit with standard center jet which achieved an average ROP of 89 feet per hour. The same bit with a Multiport Center Jet nozzle drilled the next 17 1/2 inch section to 4500 feet at an average of 103 feet per hour, achieving both greater footage and faster ROP.